Snow plough PRONAR PUV1350/1500/1800/2000M

Snow plough PRONAR PUV1350/1500/1800/2000M is designed to remove snow from the surface of roads, squares, car parks and other paved road and pavement surfaces, such as: asphalt, concrete and paving stones, concrete.

Snow plough PRONAR PUV1350/1500/1800/2000M may be aggregate with slow-speed vehicles, e.g., agricultural tractors, loaders, etc;

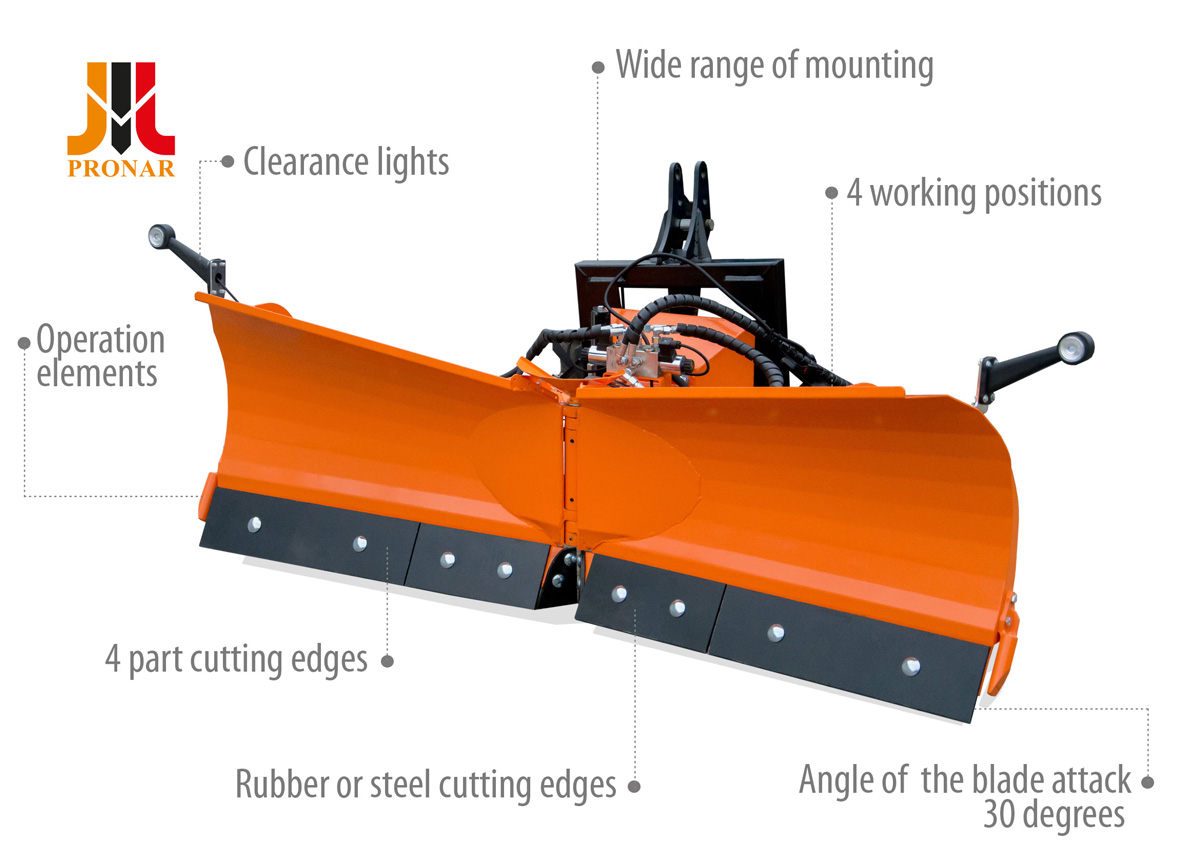

Snow plough PRONAR PUV1350/1500/1800/2000M works well in narrow alleys, on footpaths, car parks and farms. It is characterized by a durable construction, modernized shape of the mouldboard, which reduces resistance of movement and aggressive angle of the blade attack, which facilitate snow removal. Additionally, the costs of spare parts have been reduced by dividing the cutting edges into four parts (PUV1350M has two undivided cutting edges). Snow plough PRONAR PUV1350/1500/1800/2000M is easy to use – the operator can choose from four working positions, electrohydraulically set from the operator’s cabin.

Snow plough PRONAR PUV1350/1500/1800/2000M:

Wide range of mounting

The PUV-M series of snow ploughs can be adapted to work on any , meeting the requirements carriers such as: excavators, front loaders, on carriers equipped with A-frame and agricultural tractors.

4 part cutting edges

The costs of spare parts have been reduced by dividing cutting edge into four parts – only one part of cutting edge (except PUV-1350, which has undivided cutting edges) can be changed easily and cheaply.

4 working positions

Using a solenoid valve, the operator can easily set the plough position without leaving the cab . In standard version, all ploughs are equipped in four working positions. It is possible to: control each mouldboard separately or two at the same time.

Rubber or steel cutting edges

Depending on the needs, it is possible to choose rubber (for protecting the surface) or steel (for more effective stripping of icy) cutting edges.

Angle of the blade attack 30 degrees

Choosing of settings steel cutting edges perpendicularly or at an angle of 30° to the ground allows for better removal of even heavily frozen snow.

Clearance lights

The Clearance lights are standard equipment to ensure safe operation, not only after dark.

Operation elements

Depending on the needs, there is a possibility of choosing supporting wheels (to protect snow cleared surface) or less expensive skids (when you do not remove snow from paved surfaces, e.g. asphalt)

| Technical details of standard version | PUV-1350M | PUV-1500M | PUV-1800M | PUV-2000M | |

| Mounting | 3-point hitch Cat. I/0, rigid | ||||

| Working width | 1190 – 1350 | 1325 – 1500 | 1580 – 1800 | 1750 – 2000 | mm |

| Number of working positions | 4 | ||||

| Cutting edges | rubber, vertical | ||||

| Shock absorption of the cutting edge | springs | ||||

| Control | electrohydraulic | ||||

| Hydaulic power supply | 16-20 | MPa | |||

| Electric power supply | 12 | V | |||

| Clearance lights | Standard | ||||

| Working speed | 10 | km/h | |||

| Power demand | up to 30 | 30 / 50 | HP | ||

| Weight | 131 | 140 | 173 | 183 | kg |

| Additional equipment (option) : | PUV-1350M | PUV-1500M | PUV-1800M | PUV-2000M |

| Skids | – | – | x | x |

| Supporting wheels | – | – | x | x |

| Hydraulic shock absorption | x | x | x | x |

| Independent and simultanous control | x | x | x | x |

| Steel blades with 30 degrees angle (without bumpers) | x | x | x | x |

| Steel blades with 90 degrees angle (without bumpers) | x | x | x | x |

| Perforated steel blade with 30 degrees angle (without bumpers) | x | x | x | x |

| Bumpers for the cutting edge 90 degrees | x | x | x | x |

| Bumpers for the cutting edge 30 degrees | x | x | x | x |

| Lighter socket splitter | x | x | x | x |

| No clearance lights | x | x | x | x |

| 3-point hitch Cat. II, swing suspension | x | x | x | x |

| 3-point hitch Cat. I/0, swing | x | x | x | x |

| WEIDEMANN 2070CX50 mounting frame – swing | x | x | x | x |

| A-Frame I/I narrow – swing | x | x | x | x |

| GIANT 452 mounting frame- swing | x | x | x | x |